Robotic Coping Machines Crossword

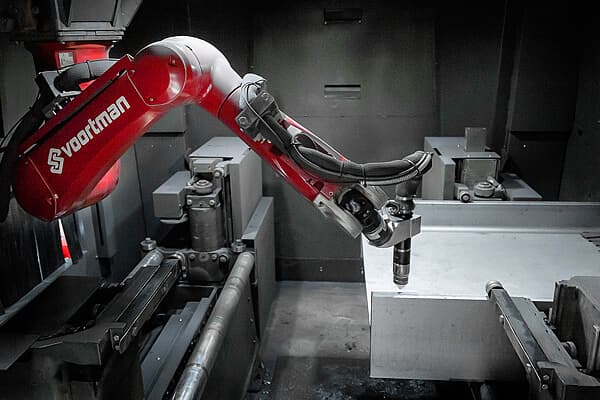

Voortman�s V808 robotic heating cutting machine, like all others, comes with the VACAM software. This allows all machines to speak the same "language". The V808 has a lot of versatility and can be used either as a part of a new layout that includes roller conveyors, cross-transports, and other Voortman processing machines or as a standalone center.

We pride ourselves on making fabrication tasks simple and efficient. The Robotic Coping and Profiling beam is designed to handle both square tubes and angle bars. It can also process pipes, T bars, plates, and bulbs. You can do anything you want with our Coping and Profiling Robots. The quality of its outputs is unmatched. These outputs can include H, I andT beams, U, and L channels, respectively.